Skid Conveyor Systems

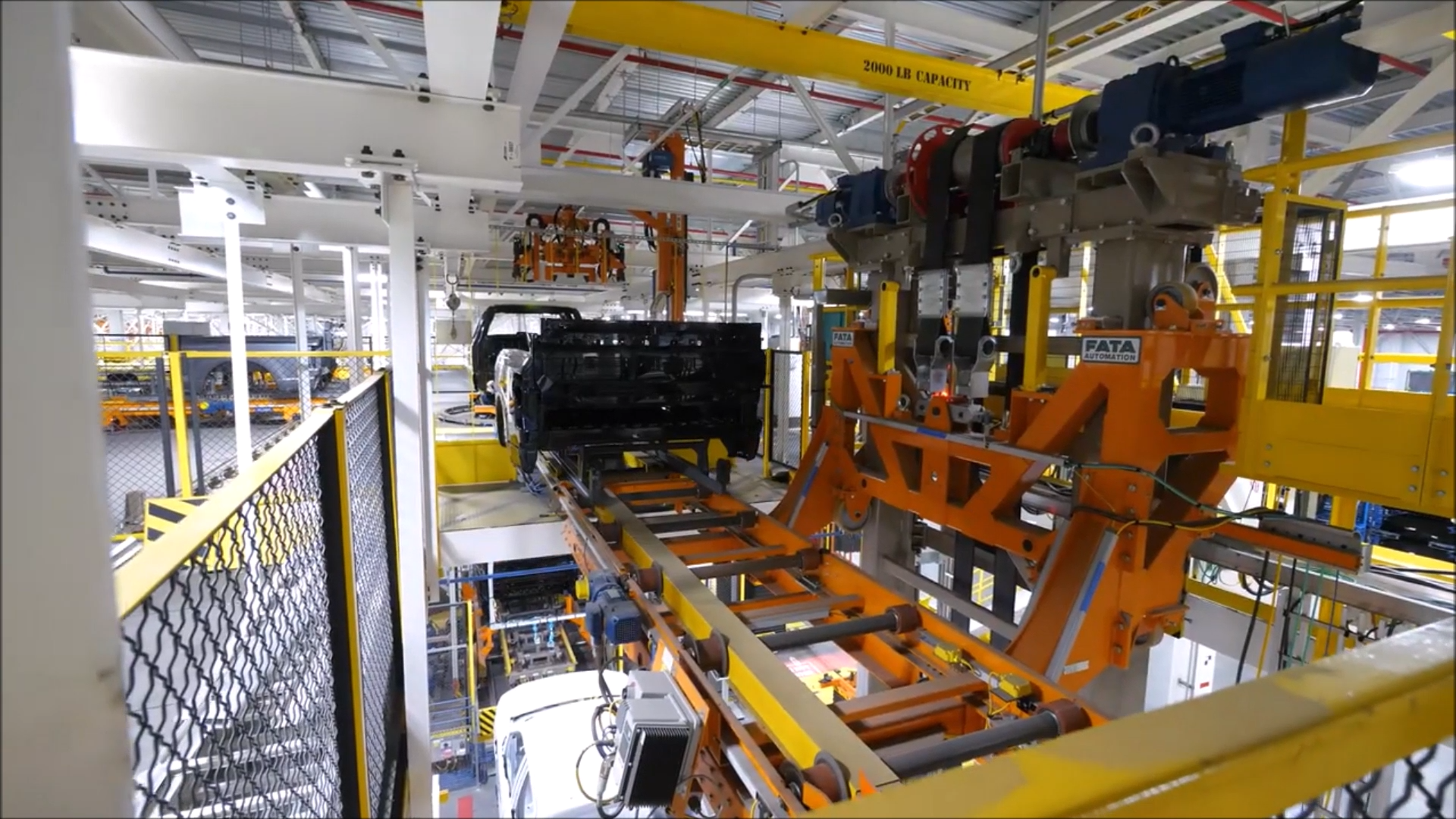

Fata Automation is a global leader in the supply of skid conveyor systems with installations dating back to 1977. We have over 175 systems installed, amounting to over 80 miles (130 km) of conveyor.

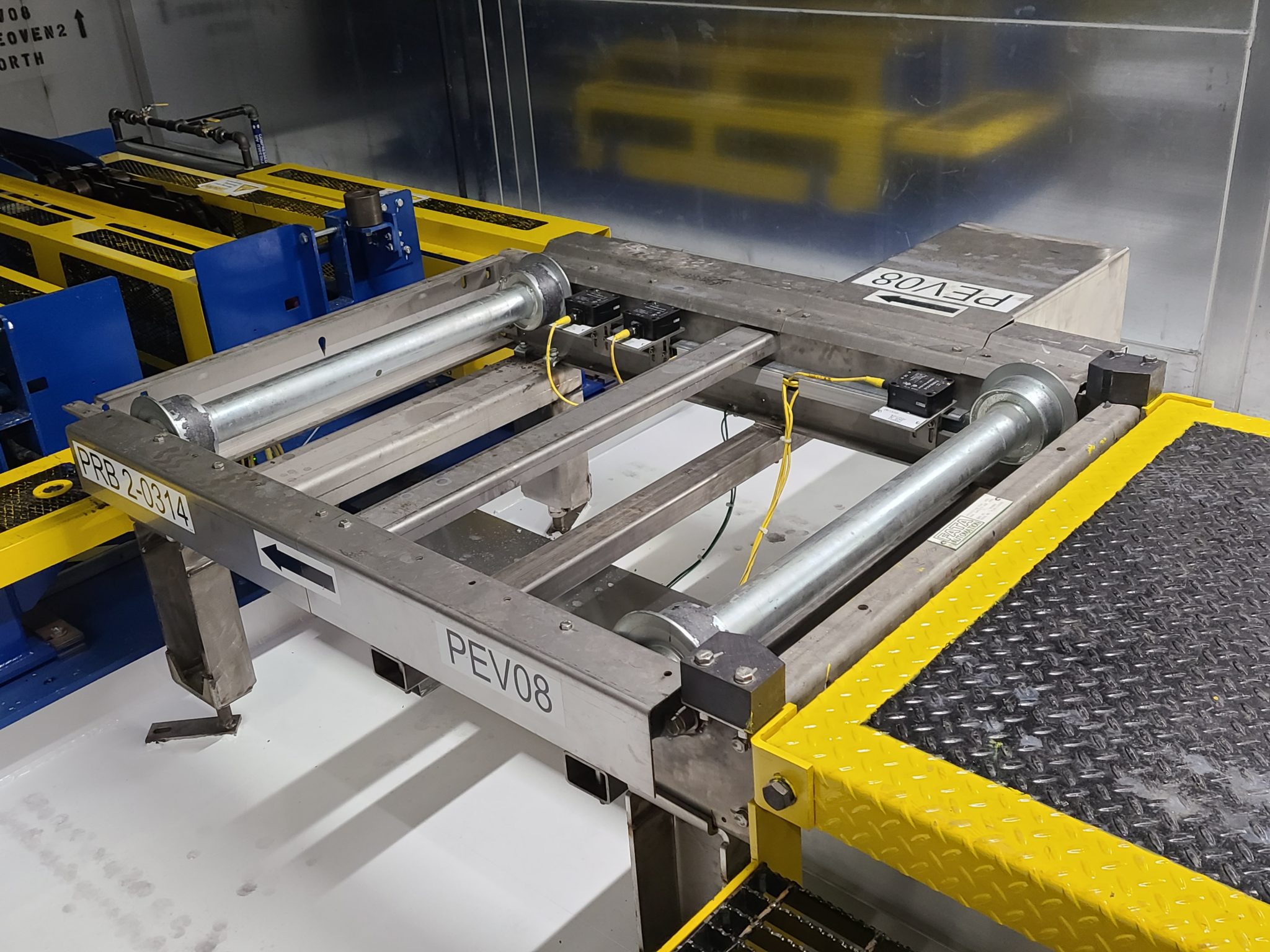

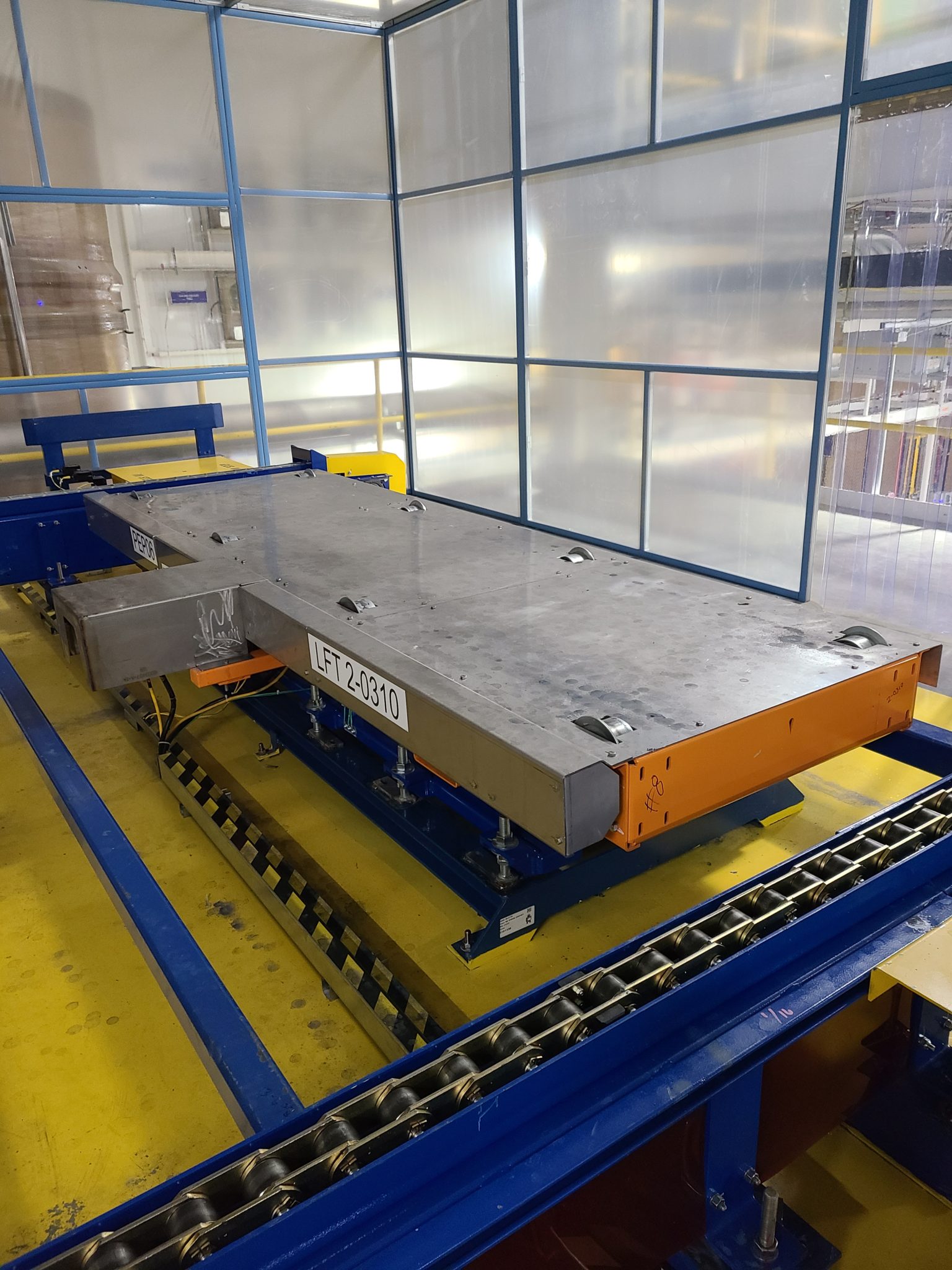

Skid conveyor transfers a product carried on fixtures with two longitudinal runners called skids. Skid systems offer an efficient and quiet mode of transport of skids in both longitudinal and transverse directions. Standard designs are available for both dry and wet area applications up to 1500 kg (3300 lbs.) load with roller bed transfer speeds up 108 mpm 354 fpm. Custom engineered designs are also available for loads up to 4600 kg (10,000 lbs.)

Skid conveyor products are modular in design that have on-board electrical components such as VFD, switches, cords, and trunk cables as a complete module using common components such as belts, rollers, and motors.

The advantages of Skid Systems Include

- High/variable Speed Process Capabilities

- Repeatability at +/- 2mm

- Modular Component Design

- Multiple Product Capability

- Wide Range of Conveyor Speeds, Production Centers, and Production Rates

- Negligible Downtime Potential

- Minimal Downtime for Model Changeover

- No Lubrication System Requirement

- No Impact Accumulation

- Quiet Operation

Skid Conveyor Products Include the Following:

- Powered Roll Beds

- Cross Transfer Conveyors (Belt/ Chain/ Plastic Chain)

- Eccentric Lift Roll Pop-Up/Hold Tables (Used w/ Cross Transfers)

- Turn/Pivot Tables

- Shuttle Tables

- Lift Tables (Eccentric/Scissor)

- Production Conveyors (Chain/Belt)

- Vertical Drop Lifts

- Stacker/De-stackers

- Accumulation Conveyors

- Docking Station/Skid Pull-Off

- Positioners

- Skid Bases

Skid Conveyor Special Products Include the Following:

- Skid Lock/ Unlock Device

- Shuttle Rotate

- Cross Transfer Shuttle

- Tilt Table

- Custom engineered designs are available for unique applications and special heavy loads.

Photo Gallery