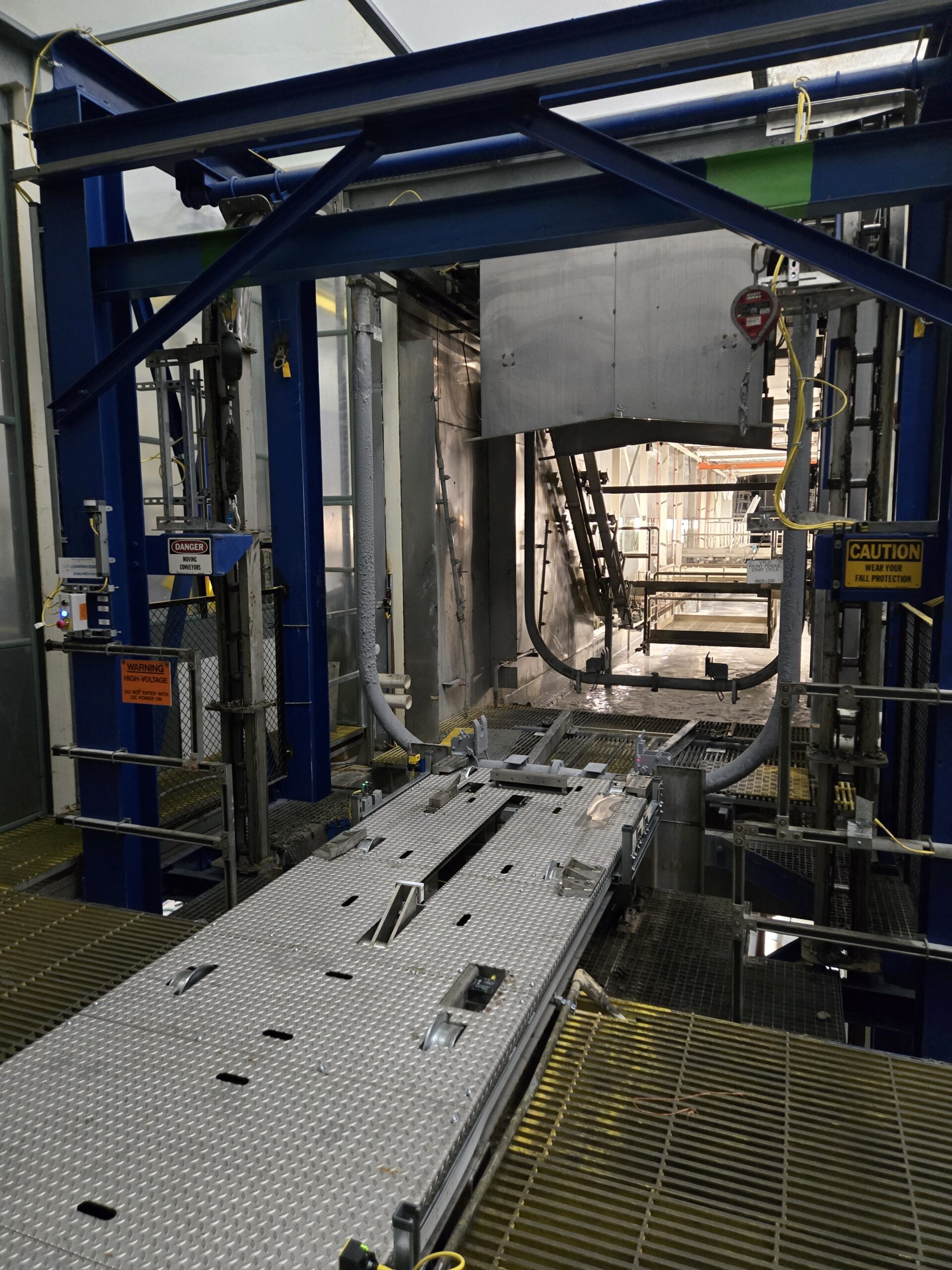

Pendulum Conveyors

Pendulum Conveyors are designed to carry skids with vehicle bodies through the pre-treatment and electro-coating (PTED) baths in a paint shop. Although this style of conveyor has been around for a while, it has been considered to be one of the most robust and dependable systems available. FATA Automation designed and installed one over 20 years ago at General Motors Lansing-Grand River that is still in operation today and is considered GM’s most reliable PTED conveyor system.

Penduls (hangers) hold vehicle skids in place to ensure that the bodies are completely treated by the liquids prior to moving on to the other paint processes.

- Some of the features of FATA Pendulum Conveyors include:

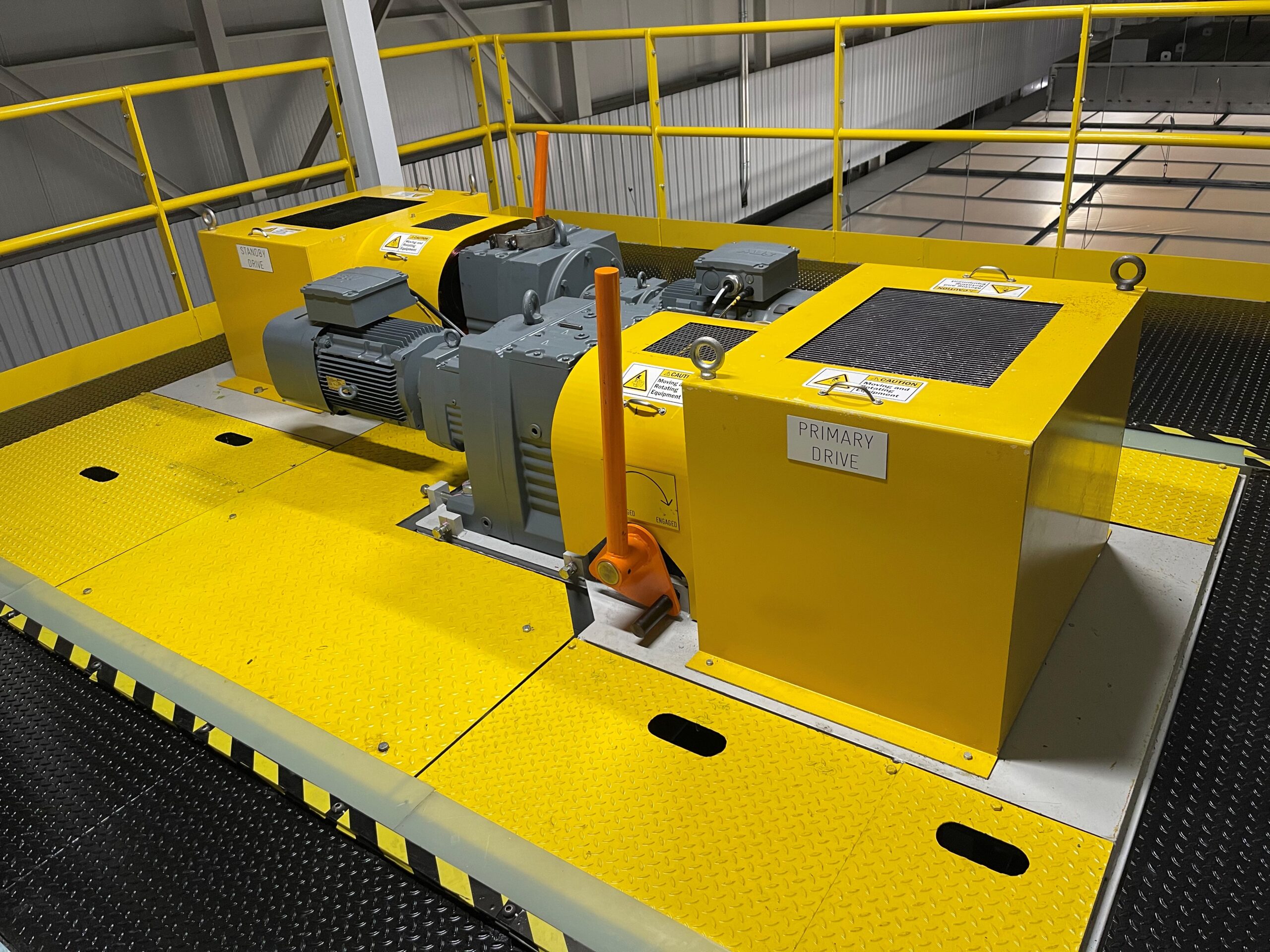

- Caterpillar Drive Units

- Two (2) transfer chain strands within an enclosed track

- Tubular U-shaped penduls (hangers)

- A gravity take-up system to maintain chain tension under varying load conditions

- Skid locking mechanism to hold skids on the penduls

- Skid unlocking mechanism to release skids prior to their delivery to the exit roll table

- Underneath vertical return run to save space

- Auto-lubrication systems for the drive, transmission, and transfer chains

Sensors for sending pendul location and other information to the control panel PLC