FATA Automation was challenged to develop an automated parking system for a medical facility in Brooklyn, New York. The area has no parking available, and the new building could not be made taller to accommodate a parking deck, due to city ordinances.

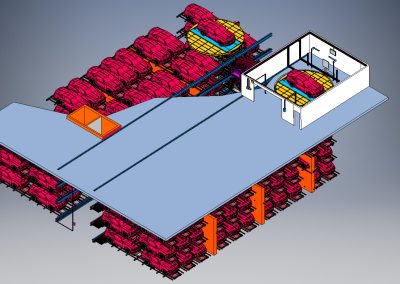

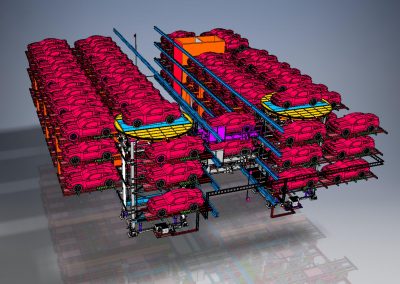

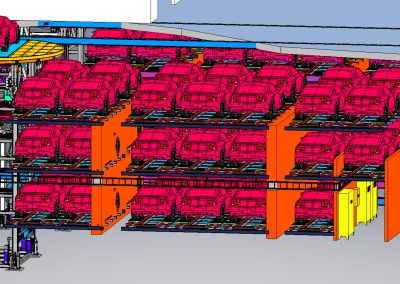

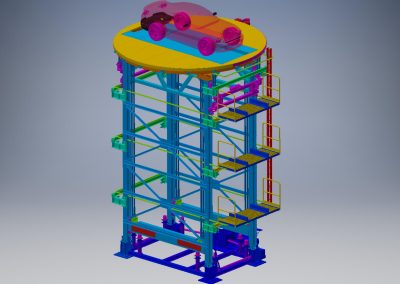

This left the Owner with only one option – Dig 3 levels under the building and install automated parking to get the vehicles down there and to park the greatest possible number of vehicles in the smallest space.

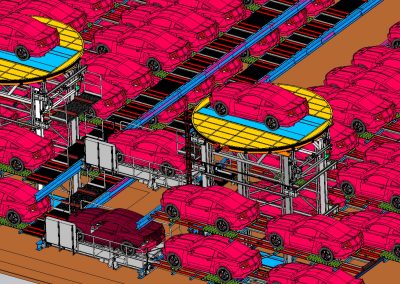

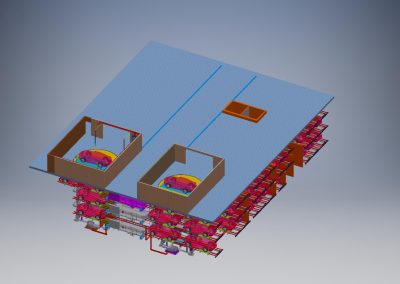

The system developed by FATA uses two Entry

In order to make retrieval of the vehicles fast and efficient, FATA also developed software that works in a “traffic cop” fashion to make and change decisions on which vehicle goes when – keeping cycle times fast and customer wait times as short as possible.

The system parks 131 vehicles and is expected to be operational in the Summer of 2019.